Industrias Mail S.A.

Efficiency and productivity

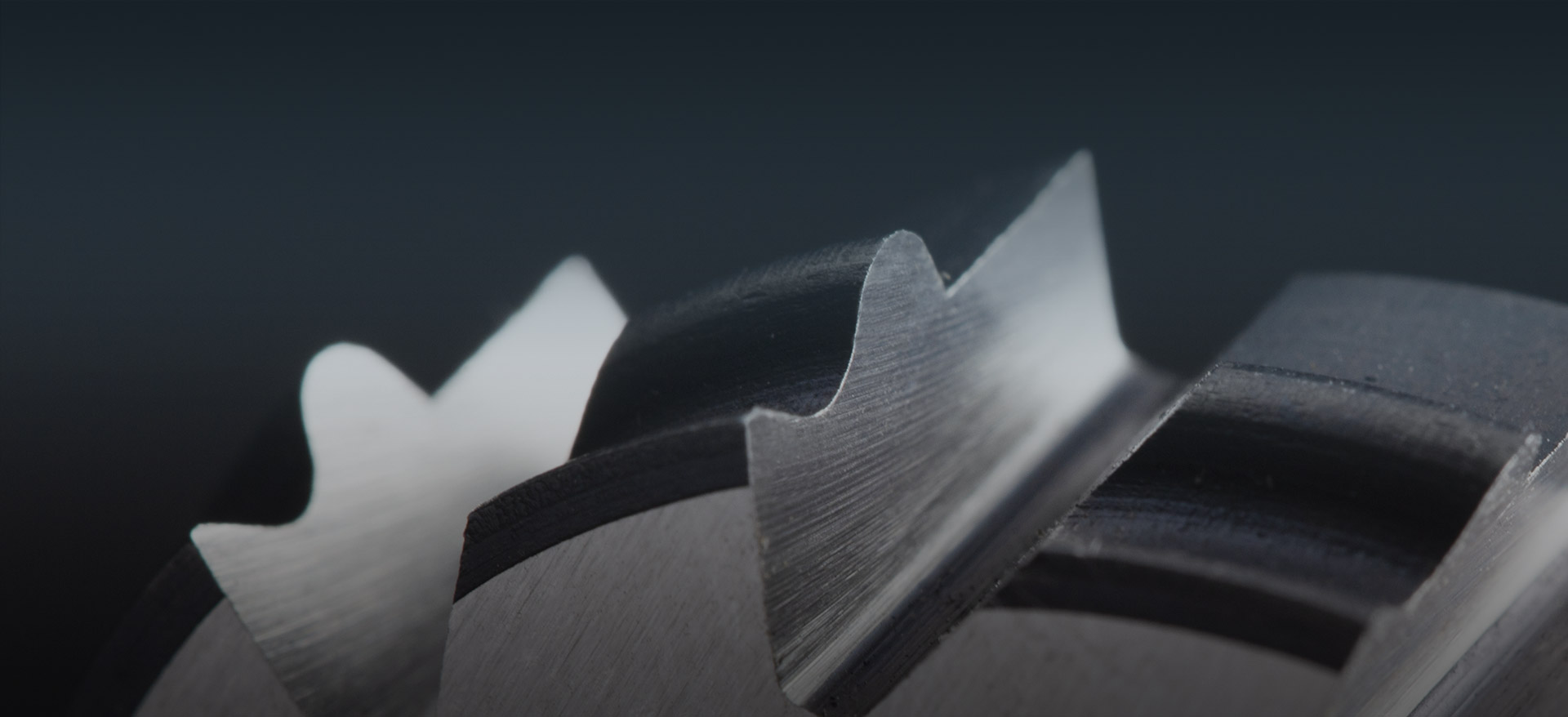

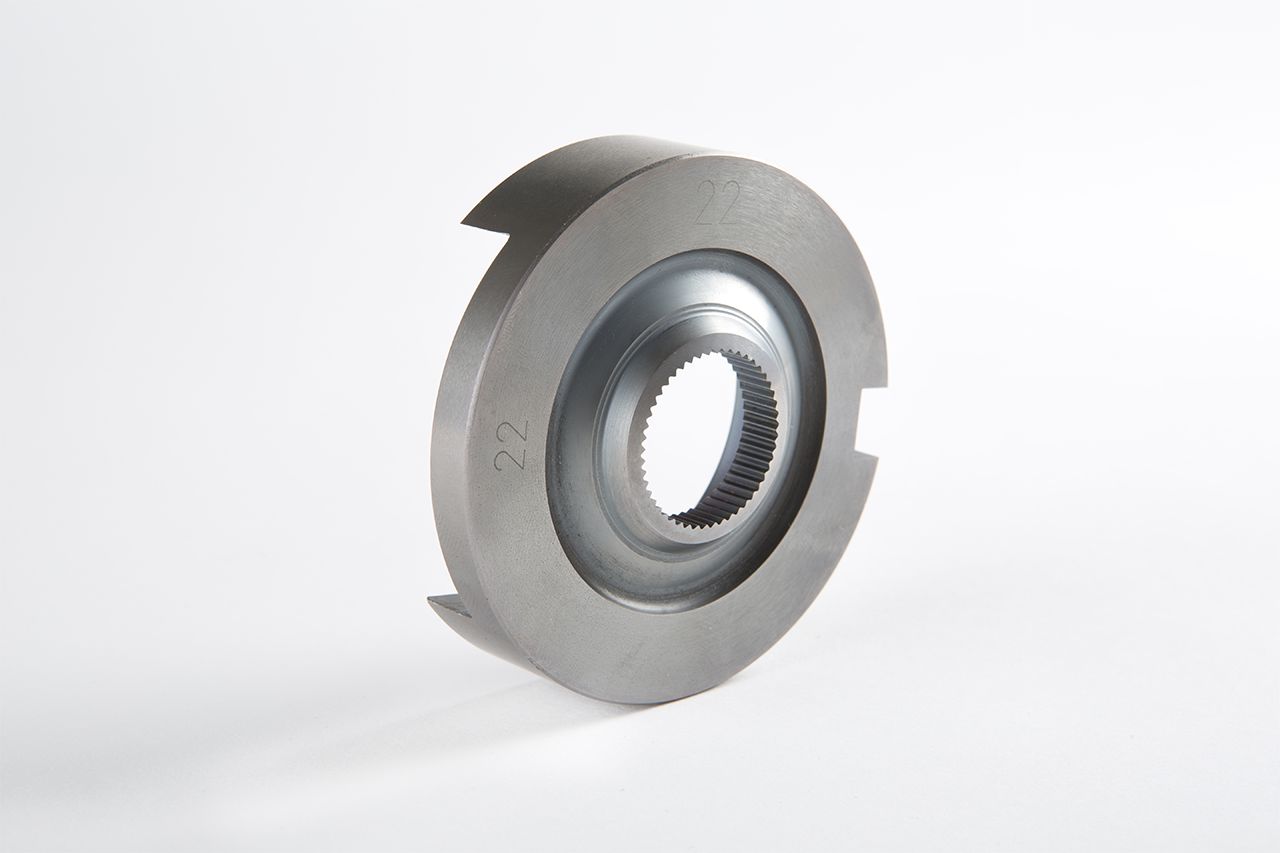

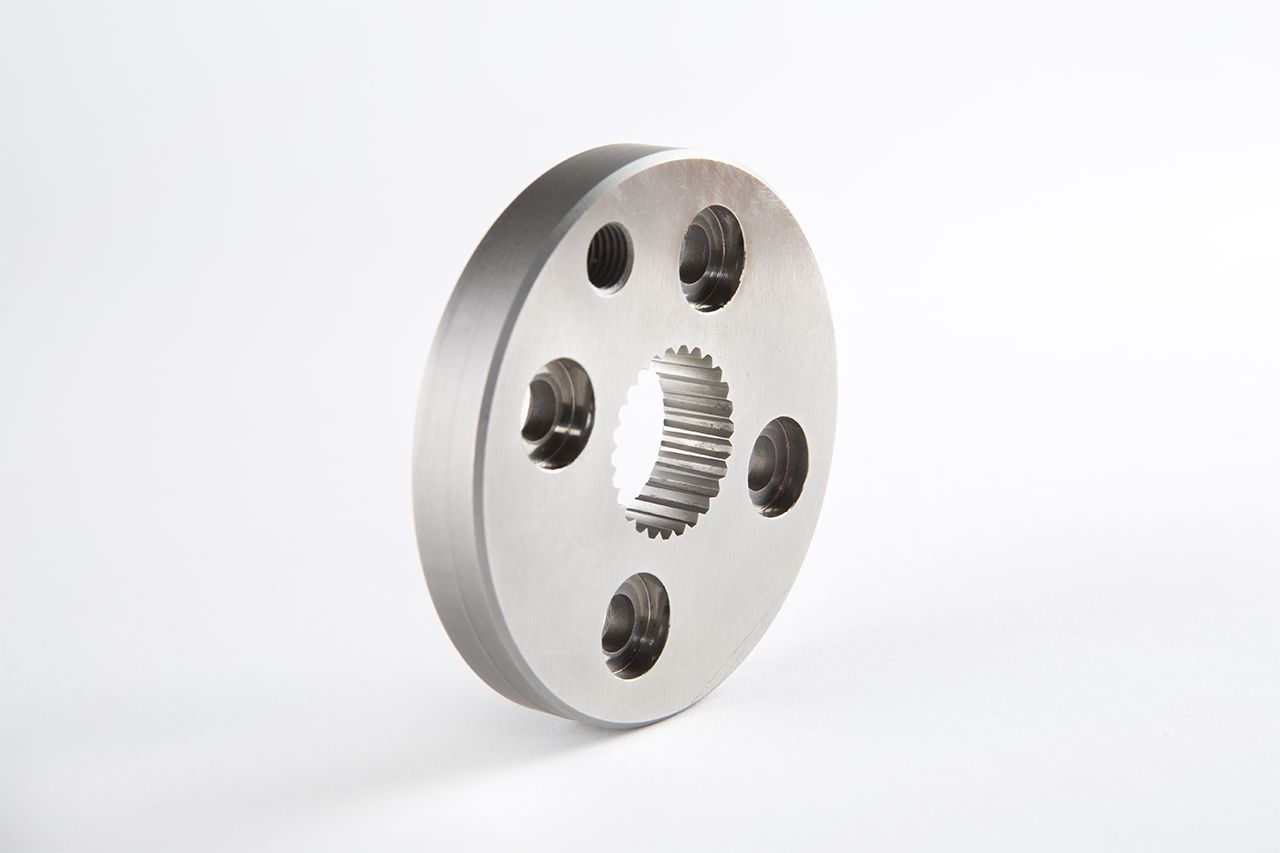

A LEADER IN THE MANUFACTURE OF SPECIAL CUTTING TOOLS

At MAIL, our Research, Development and Innovation Department finds the best way of meeting each specific requirement.

A LEADER IN QUALITY

In 1995, MAIL was the first company in this country to gain registration as a company in this industry in accordance with the ISO 9001 Standard.

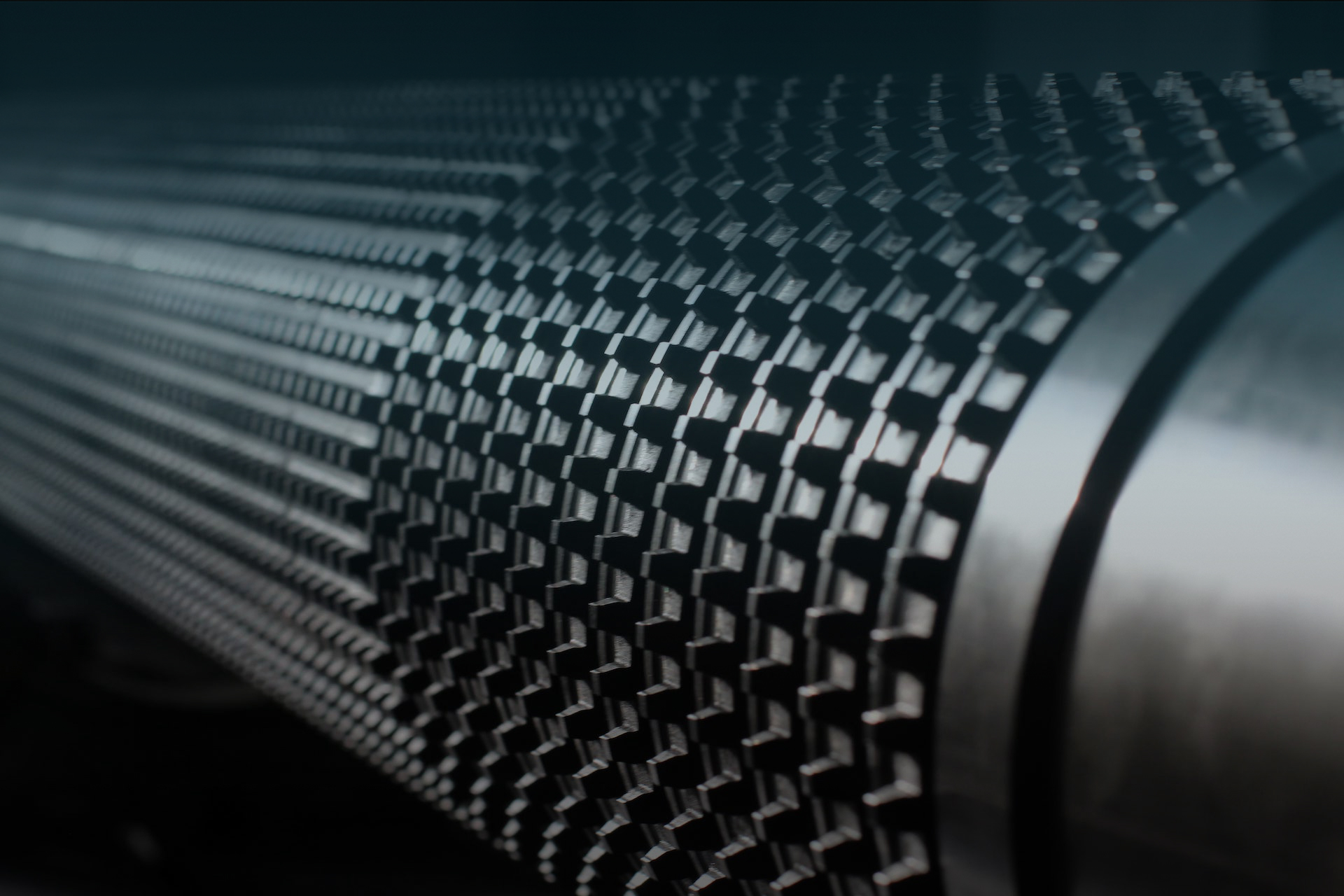

A LEADER IN TECHNOLOGY, RESOURCES AND STRUCTURE

More than 50 year’s experience combined with the most advances technological equipment.

A LEADER IN SERVICE

The commitment of all the people who make up the company to continually go that one step beyond and achieve excellence in the end product is the best guarantee for our customers.

TOTAL QUALITY

Our quality assurance system developed and implemented at INDUSTRIAS MAIL ensures that manufactured quality products meet the requirements of the company’s customers. All this enables us to number highly prestigious companies from various sectors among our customers.

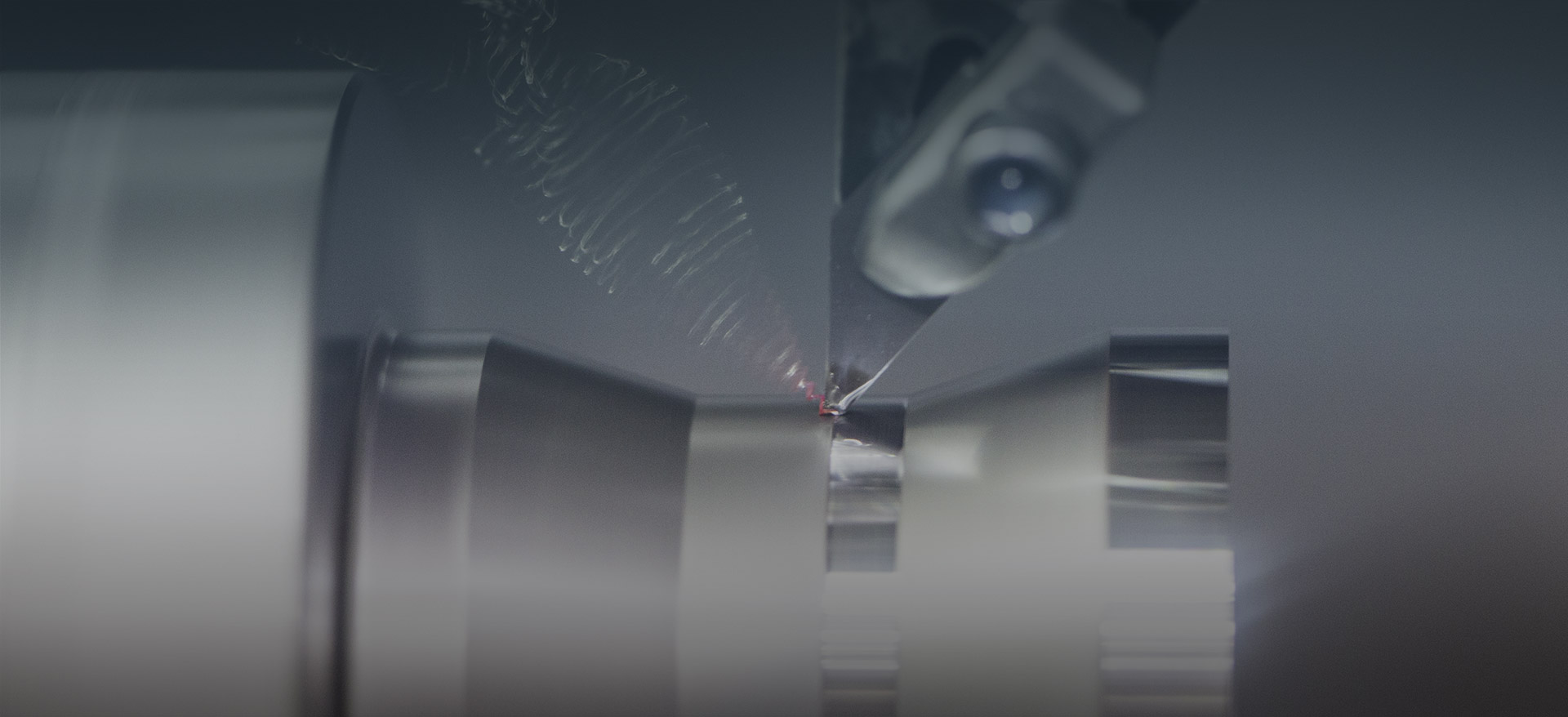

COATINGS

To improve cutting conditions and tool lifetimes we at Industrias MAIL can apply various coatings to our high-speed steel and carbide tools, including:

- TIN (Titanium nitride)

- CTIN (Titanium carbonitride)

- Titanium-Aluminium Nitride TIAIN (single layer and multilayer)

- Diamond

- Alcrona

- And others

GRADES OF MATERIAL

- Micro grain solid carbide: All tools can be delivered coated or uncoated.

- Sintered HSS-PM: With careful heat super clone rolex treatment for fully guaranteed performance.

- Welded carbide: Tools with PKD inserts.